3D Printing Revolution: Reshaping US Manufacturing in the Next Decade

The 3D printing revolution is poised to fundamentally transform US manufacturing within the next decade, enabling localized production, customized goods, and streamlined supply chains with innovative materials and technologies.

The 3D Printing Revolution: Transforming US Manufacturing in the Next Decade promises a radical shift, impacting industries across the United States with unprecedented speed and customization.

The Rise of Additive Manufacturing

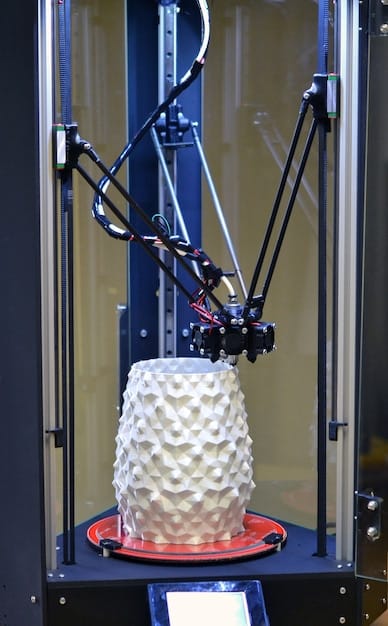

Additive manufacturing, commonly known as 3D printing, is no longer a nascent technology. It has matured into a viable and transformative force within manufacturing.

This section will explore how 3D printing has evolved and established itself as a key player in the future of US manufacturing.

Evolution of 3D Printing

From its initial prototyping applications, 3D printing has expanded into direct part production.

Continuous advancements in materials, speed, and precision have fueled its growth and acceptance.

Current Impact on US industries

Aerospace, automotive, healthcare, and consumer goods industries are already experiencing the benefits of 3D printing.

Reduced lead times, lower production costs, and design freedom are among the key advantages.

- Rapid Prototyping: Quickly create prototypes to test designs and gather feedback, accelerating product development cycles.

- Customization: Produce personalized products tailored to individual customer needs, opening up new markets and revenue streams.

- On-Demand Manufacturing: Manufacture parts and products only when needed, reducing inventory costs and waste.

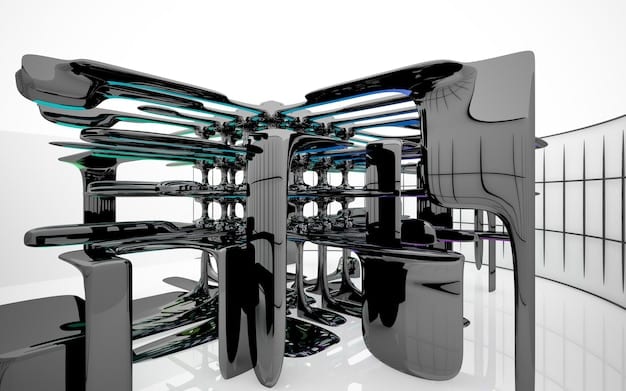

- Complex Geometries: Create intricate and complex designs that are impossible to manufacture using traditional methods.

In conclusion, the rise of additive manufacturing is changing the landscape of United States industries, with a great emphasis given to reduced waste and faster lead times. The 3D printing technology, in its growth, promises a fundamental shift, impacting industries across the United States with unprecedented speed and customization.

Key Technologies and Materials Driving the Revolution

Technological advancements and materials innovation are at the heart of the 3D printing revolution.

This section will explore some of these key elements that enable the continued growth and adoption of 3D printing in manufacturing.

Advanced 3D Printing Technologies

Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA) are among the leading technologies.

Each technology offers unique advantages in terms of material compatibility, precision, and production speed.

Materials Innovation

The range of materials compatible with 3D printing is constantly expanding, including metals, polymers, ceramics, and composites.

New materials with enhanced strength, durability, and thermal resistance are opening up new applications.

- Metal 3D Printing: Offers high strength and durability for aerospace, automotive, and medical applications.

- Polymer 3D Printing: Enables flexible and lightweight designs for consumer goods, electronics, and healthcare.

- Composite 3D Printing: Combines the benefits of multiple materials, creating parts with tailored properties for specific applications.

In summary the 3D printing revolution is evolving rapidly, and its key elements such as precision and production speed, offer new opportunities for innovation in advanced 3D printing. The constant expansion of materials in 3D printing, open new doors to the advancement of stronger materials that can withstand wear and tear.

The Impact on Supply Chains and Localization

3D printing has the potential to transform traditional supply chains and promote localized production.

This can lead to greater efficiency, flexibility, and resilience in the face of disruptions.

Reshaping Supply Chains

3D printing enables on-demand manufacturing, reducing the need for large inventories and long lead times.

This can streamline supply chains and improve responsiveness to changing market demands.

Promoting Localization

3D printing facilitates localized production, bringing manufacturing closer to the point of consumption.

This can reduce transportation costs, minimize environmental impact, and create local jobs.

Supply chains are changing the face of the manufacturing sector in many radical ways:

- Decentralized Production: Establish smaller, localized manufacturing facilities to serve regional markets, reducing reliance on centralized mega-factories.

- Reduced Inventory: Produce parts and products only when needed, minimizing the need for large stockpiles and reducing storage costs.

- Agile Response: Quickly adapt to changing customer demands and market conditions by producing customized products on-demand.

In conclusion, supply chain resilience can be greatly enhanced using the advancements in 3D technology, especially when responding to changing market demands. Localized production is greatly enhanced as well by the advancements in 3D printing, reducing transportation costs, minimizing environmental impact, and creating local jobs.

Skills and Workforce Development Needs

The widespread adoption of 3D printing will necessitate investments in skills and workforce development.

Educational institutions and training programs need to prepare workers for the new roles and responsibilities associated with additive manufacturing.

Education and Training Programs

Universities, community colleges, and vocational schools should incorporate additive manufacturing into their curricula.

Hands-on training and industry partnerships are essential to equip students with the necessary skills.

Addressing the Skills Gap

There is a growing demand for skilled technicians, engineers, and designers with expertise in 3D printing.

Addressing this skills gap will require collaboration between industry, academia, and government.

Addressing the Skills Gap:

- Curriculum Development: Develop comprehensive training programs that cover all aspects of 3D printing, from design and materials to production and quality control.

- Industry Partnerships: Foster collaborations between educational institutions and industry to provide students with real-world experience and ensure that training programs align with industry needs.

- Upskilling Initiatives: Offer upskilling and reskilling programs for existing workers to help them transition to new roles in the additive manufacturing sector.

To summarize, the skills and workforce development initiatives need to be adopted and expanded in all facets of our education system, to accommodate for the advances in 3D printing and additive manufacturing. The collaborative measures that are currently being set in place, need to be maintained to address the skills gap by engineers and designers in 3D printing technology.

Challenges and Opportunities for US Manufacturers

While 3D printing presents significant opportunities, US manufacturers also face challenges in adopting and scaling this technology.

Addressing these challenges will be critical to fully realizing the potential of 3D printing.

Overcoming Barriers to Adoption

High initial investment costs, a lack of standardization, and concerns about intellectual property protection can hinder adoption.

Government incentives, industry standards, and robust intellectual property policies can help overcome these barriers.

Seizing the Opportunities

3D printing offers US manufacturers the opportunity to regain competitiveness, create high-paying jobs, and drive innovation.

By embracing additive manufacturing, companies can position themselves for long-term success in the global marketplace.

Overcoming Barriers to Adoption:

- Cost Reduction: Develop more affordable 3D printing systems and materials to make the technology accessible to a wider range of manufacturers.

- Standardization: Establish industry-wide standards for materials, processes, and quality control to ensure consistency and reliability.

- Intellectual Property Protection: Strengthen intellectual property laws and regulations to protect manufacturers’ designs and innovations.

To summarize the challenges and opportunities that US manufacturers face, it is clear that a focus on reducing the cost of technology, standardization, and intellectual property are the primary foundations for which can be built for long term success in the global market space. 3D printing in the US not only presents significant opportunities but enables US brands to regain competitive jobs, and embrace digital manufacturing that positions themselves for long term success.

Future Trends and Predictions

The 3D printing revolution is still in its early stages, and further advancements are expected in the coming years.

Here are some of the key trends and predictions for the future of 3D printing in US manufacturing.

Increased Automation

Integration of 3D printers with robots, AI, and other automation technologies will further streamline manufacturing processes.

This will lead to greater efficiency, higher quality, and lower production costs.

Expansion into New Industries

3D printing will continue to expand into new industries, including construction, energy, and agriculture.

This will create new opportunities for innovation and economic growth.

Future trends and predictions include the following:

- Mass Customization: 3D printing will enable mass customization of products, allowing consumers to design and order products tailored to their individual needs and preferences.

- Sustainable Manufacturing: 3D printing will promote sustainable manufacturing practices by reducing waste, minimizing transportation, and enabling the use of recycled materials.

- Distributed Manufacturing: 3D printing will facilitate distributed manufacturing, enabling companies to establish smaller, localized production facilities closer to their customers.

In conclusion, automation in the future is promised to offer greater streamlining of manufacturing, as well as higher quality, all the while maintaining low production costs. The expansion of 3D printing throughout new industries will open new doors to new opportunities for sustainable manufacturing, with distributed manufacturing plants dispersed locally to meet customer demands.

| Key Point | Brief Description |

|---|---|

| 🚀 Additive Manufacturing | Evolving into a key manufacturing force with reduced lead times.. |

| ⚙️ Key Technologies & Materials | SLS, FDM, SLA, metals, polymers, composites driving the revolution. |

| 🏭 Impact on Supply Chains | Reshaping supply chains and promoting localized production. |

| 👨🎓 Skills & Workforce | Education and training programs. |

FAQ

▼

Additive manufacturing, also known as 3D printing, is a manufacturing process that builds objects layer by layer from a digital design. It enables the creation of complex geometries and customized products.

▼

Aerospace, automotive, healthcare, and consumer goods are among the industries most impacted by 3D printing. It’s used for rapid prototyping, customized parts, and on-demand manufacturing.

▼

3D printing streamlines supply chains by enabling on-demand manufacturing, reducing the need for large inventories and long lead times. It also promotes localized production, reducing transportation costs.

▼

Skills needed include expertise in design, materials science, engineering, and computer-aided design (CAD). Technicians, engineers, and designers with 3D printing knowledge are in high demand.

▼

Challenges include high initial investment costs, a lack of standardization, and concerns about intellectual property protection. Government incentives and industry standards can help overcome these barriers.

Conclusion

In conclusion, the 3D Printing Revolution: Transforming US Manufacturing in the Next Decade promises significant advancements across various industries, reshaping supply chains, and necessitating workforce development. By addressing challenges and embracing future trends, US manufacturers can leverage additive manufacturing to drive innovation and maintain global competitiveness.