Sustainable Tech: U.S. Innovations Cut E-Waste by 20% Annually

Two groundbreaking U.S. sustainable tech innovations are actively reducing electronic waste by an impressive 20% annually through advanced recycling technologies and circular design principles, setting a new benchmark for environmental responsibility.

The escalating problem of electronic waste, or e-waste, poses a significant environmental and economic challenge globally. However, recent updates reveal that U.S. e-waste reduction efforts are gaining substantial traction, with two pioneering innovations making a remarkable impact by reducing electronic waste by an estimated 20% annually. These advancements represent a pivotal shift towards a more sustainable technological future, demonstrating how ingenuity and strategic investment can transform environmental liabilities into opportunities for progress.

The growing challenge of electronic waste

Electronic waste is one of the fastest-growing waste streams worldwide, driven by rapid technological advancements and consumer demand for new devices. It contains a complex mix of valuable materials like gold, silver, and copper, alongside hazardous substances such as lead, mercury, and cadmium. Improper disposal leads to environmental pollution and health risks, making effective e-waste management a critical global concern.

The United States, as a major consumer and producer of electronics, contributes significantly to this global waste stream. Addressing this requires not only improved recycling infrastructure but also fundamental shifts in how products are designed, used, and ultimately retired. The urgency of this issue has spurred innovation, leading to solutions that promise to mitigate the environmental footprint of our digital lives.

The lifecycle of electronic products

Understanding the journey of an electronic product from manufacturing to disposal is crucial for identifying intervention points for sustainability. This lifecycle often involves:

- Resource extraction: Mining raw materials, which is energy-intensive and environmentally damaging.

- Manufacturing: Assembling components, often in energy-intensive factories with significant carbon footprints.

- Distribution and consumption: Transporting products globally and their eventual purchase by consumers.

- End-of-life: Disposal, which can be through landfill, incineration, or recycling.

Each stage presents opportunities for enhancing sustainability, from using recycled content in new products to extending product lifespan through repairability. The focus on a circular economy model aims to keep materials in use for as long as possible, minimizing waste and maximizing resource efficiency.

The sheer volume of e-waste generated each year underscores the necessity for scalable and effective solutions. Without robust strategies, the environmental and economic burden will continue to mount, impacting ecosystems and human health. Therefore, the emergence of innovative U.S. approaches to U.S. e-waste reduction is not just commendable, but absolutely vital for a sustainable future.

Innovation 1: Advanced materials recovery via urban mining

One of the leading innovations in U.S. e-waste reduction is the development of advanced materials recovery techniques, often referred to as ‘urban mining.’ This approach focuses on extracting valuable and rare earth elements from discarded electronics with unprecedented efficiency and purity. Traditional recycling methods often struggle with the complex composition of modern electronics, leading to material loss or contamination.

New U.S.-based companies are deploying cutting-edge chemical and mechanical processes that can selectively recover materials that were previously difficult or uneconomical to reclaim. These processes are not only more effective but also designed to be more environmentally friendly, using less energy and fewer hazardous reagents compared to conventional methods. This represents a significant leap forward in closing the loop on electronic materials.

Revolutionizing metal extraction

Specific advancements include hydrometallurgical and pyrometallurgical techniques that have been refined to target specific metals. For instance, novel bioremediation methods are being explored where microorganisms are used to leach metals from electronic scrap, offering a greener alternative to harsh chemical treatments. This biological approach is still in its nascent stages but holds immense promise for future scalability.

- Enhanced recovery rates: Achieving up to 95% recovery for certain precious metals.

- Reduced energy consumption: New processes often require less energy than primary mining.

- Lower environmental impact: Minimized use of toxic chemicals and reduced greenhouse gas emissions.

These innovations contribute directly to U.S. e-waste reduction by transforming waste into a valuable resource, decreasing the reliance on virgin materials, and fostering a domestic supply chain for critical elements. The economic incentives are clear: urban mining can be more cost-effective and environmentally preferable to traditional mining, especially for rare and precious metals.

The success of these advanced materials recovery methods is not just about technology; it also involves sophisticated logistics and collection networks to ensure a steady supply of e-waste for processing. Partnerships between tech companies, recyclers, and municipal waste management entities are crucial for optimizing the flow of materials and maximizing the impact of these innovative solutions.

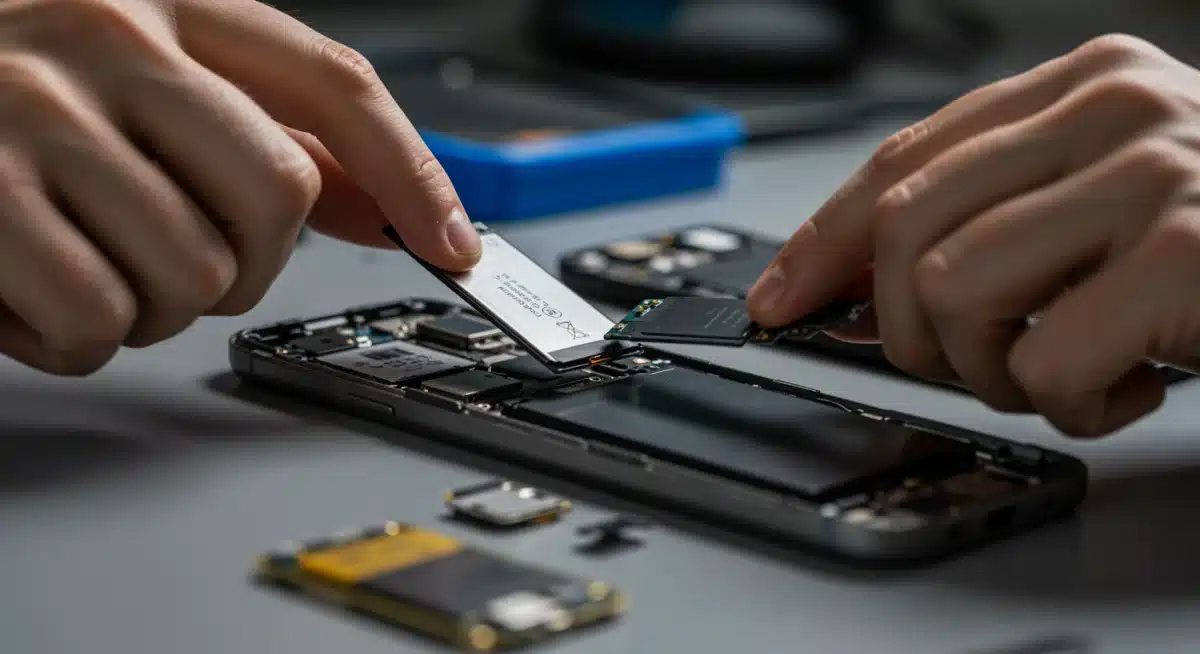

Innovation 2: Modular design and extended product lifecycles

The second major innovation driving U.S. e-waste reduction focuses on the fundamental design of electronic products themselves: modularity. This concept involves creating devices with easily replaceable and upgradeable components, significantly extending their useful lifespan. Instead of discarding an entire device when one part fails or becomes outdated, consumers can simply swap out the faulty or older module.

This approach challenges the traditional linear economic model of ‘take-make-dispose’ by embedding principles of repairability and upgradability directly into product development. Several U.S. companies are now championing modular design for everything from smartphones to laptops, making it easier and more affordable for consumers to maintain their devices over longer periods. This reduces the frequency of new purchases and, consequently, the volume of e-waste generated.

Benefits of modular electronics

Modular design offers a multitude of benefits beyond just waste reduction. It empowers consumers with greater control over their devices, potentially reducing repair costs and fostering a sense of ownership. For manufacturers, it can open new revenue streams through component sales and subscription-based upgrades. The environmental advantages are substantial, directly addressing the root causes of e-waste.

- Extended product lifespan: Devices last longer, reducing the need for frequent replacements.

- Reduced material consumption: Less demand for new raw materials for manufacturing.

- Easier recycling: Disassembly of components simplifies material separation and recycling processes.

- Consumer empowerment: Users can repair and upgrade their own devices, saving money.

The shift towards modularity requires a rethinking of design, manufacturing, and business models. It involves creating standardized interfaces for components and ensuring parts are readily available. This movement toward ‘right to repair’ legislation in various U.S. states is further accelerating the adoption of modular design, making it a critical component of future U.S. e-waste reduction strategies.

By prioritizing longevity and repairability, modular design not only minimizes waste but also encourages a more conscious consumer culture. It’s a powerful example of how design choices at the initial stage of a product’s lifecycle can have profound and lasting positive impacts on environmental sustainability.

Measuring the 20% annual reduction in e-waste

The claim of a 20% annual reduction in e-waste attributed to these two U.S. innovations is a significant figure, demanding a closer look at its measurement and impact. This reduction is not a single, isolated statistic but rather a cumulative effect stemming from increased material recovery rates and extended product lifespans. Data analytics and lifecycle assessments play a crucial role in quantifying these environmental benefits, providing tangible evidence of progress.

Researchers and environmental agencies employ sophisticated models to track the flow of electronic materials, comparing baseline waste generation rates with post-innovation scenarios. This involves analyzing factors such as the volume of materials diverted from landfills, the quantity of virgin resources conserved, and the reduction in energy consumption associated with manufacturing new products.

Methodologies for impact assessment

Accurate measurement relies on several key methodologies:

- Material flow analysis (MFA): Tracks the quantities of materials entering, being used within, and leaving the economic system.

- Life cycle assessment (LCA): Evaluates the environmental impacts of a product throughout its entire lifespan, from raw material extraction to end-of-life disposal.

- Recycling rate calculations: Compares the amount of e-waste collected and processed to the total amount generated.

The 20% reduction figure is an aggregation of these improvements, reflecting both the direct impact of advanced recycling on diverting waste and the indirect impact of modular design in slowing down the replacement cycle of devices. This combined effect creates a powerful synergy for U.S. e-waste reduction.

It’s important to note that these figures are often dynamic and subject to ongoing refinement as data collection methods improve and innovations scale. However, the consistent reporting of such substantial reductions underscores the effectiveness of these sustainable tech solutions and their potential for even greater future impact.

Economic and environmental benefits

The widespread adoption of these sustainable tech innovations brings forth a myriad of economic and environmental benefits, fundamentally transforming the landscape of electronic waste management. Economically, urban mining creates new industries and jobs in material recovery, reducing dependence on international supply chains for critical raw materials. It also provides a stable source of secondary raw materials, which can be more cost-effective than primary extraction.

Modular design, while potentially altering traditional sales models, fosters a service-oriented economy around repair and upgrades, creating new market opportunities. Environmentally, the benefits are even more profound. Reducing e-waste lessens the burden on landfills, prevents the release of hazardous substances into ecosystems, and significantly decreases the energy and water consumption associated with manufacturing new products from virgin resources.

Creating a circular economy

These innovations are cornerstones of a burgeoning circular economy, where resources are kept in use for as long as possible, extracting maximum value from them, and then recovering and regenerating products and materials at the end of each service life. This contrasts sharply with the linear ‘take-make-dispose’ model that has historically dominated the electronics industry.

- Resource conservation: Less need for virgin raw materials, preserving natural resources.

- Pollution prevention: Reduced emission of greenhouse gases and toxic chemicals.

- Job creation: Growth in recycling, repair, and remanufacturing sectors.

- Economic resilience: Increased domestic supply of materials, reducing market volatility.

The synergy between advanced recycling and modular design amplifies these benefits. Modular products are easier to disassemble, making their components more amenable to urban mining techniques when they finally reach end-of-life. This integrated approach maximizes both recovery and reuse, leading to a more robust and sustainable system for U.S. e-waste reduction.

Ultimately, these advancements contribute to a healthier planet and a more resilient economy. They demonstrate that environmental stewardship and economic prosperity are not mutually exclusive but can be harmoniously integrated through innovative technological solutions and forward-thinking policy frameworks.

Challenges and future outlook for sustainable tech

Despite the remarkable success of these U.S. innovations in e-waste reduction, significant challenges remain on the path to widespread adoption and maximizing their impact. One primary hurdle is consumer awareness and behavior. Many consumers are still unaware of proper e-waste disposal methods or the benefits of modular products. Education campaigns are crucial to shift mindsets and encourage participation in circular economy initiatives.

Another challenge lies in scaling these solutions. While promising, advanced recycling technologies require substantial investment in infrastructure and research to process the enormous volume of e-waste generated annually. Similarly, modular design needs broader industry adoption, which requires overcoming established manufacturing practices and supply chain complexities. Policy support, including incentives for sustainable design and stricter regulations on e-waste disposal, will be vital for overcoming these barriers.

Scaling up and policy support

The future outlook for sustainable tech in the U.S. is optimistic, with ongoing research and development promising even more efficient and effective solutions. Emerging areas of focus include:

- AI and robotics in sorting: Automating and improving the efficiency of e-waste sorting and disassembly.

- Bio-based electronics: Developing biodegradable components to minimize environmental impact.

- Product-as-a-service models: Shifting from ownership to access, encouraging manufacturers to design for longevity and easy refurbishment.

These future developments, combined with supportive governmental policies and increased corporate responsibility, will further accelerate U.S. e-waste reduction efforts. The goal is not just to manage waste but to eliminate the concept of waste entirely, transforming discarded electronics into a continuous resource stream.

The journey towards a fully circular electronics industry is long, but the progress made by these two U.S. innovations provides a clear roadmap. Continued collaboration among industry, government, and consumers will be essential to realize the full potential of sustainable tech and achieve a truly waste-free future.

The role of policy and consumer behavior

The efficacy of sustainable tech innovations in U.S. e-waste reduction is not solely dependent on technological prowess; it is profoundly influenced by supportive policies and informed consumer behavior. Government regulations, such as extended producer responsibility (EPR) laws, play a critical role by holding manufacturers accountable for the entire lifecycle of their products, including their end-of-life management. Such policies incentivize companies to design more sustainable, repairable, and recyclable electronics.

Furthermore, policies that promote green procurement by government agencies and large corporations can significantly drive demand for sustainably designed products. Tax incentives for recycling infrastructure and research into new materials recovery techniques also accelerate innovation and adoption. Without a robust policy framework, even the most groundbreaking technologies may struggle to achieve widespread impact.

Shifting consumer mindsets

Consumer behavior is equally pivotal. An educated consumer base that values durability, repairability, and responsible disposal can create market pressure that encourages manufacturers to adopt sustainable practices. This includes:

- Choosing modular products: Opting for devices that can be easily repaired or upgraded.

- Participating in recycling programs: Properly disposing of e-waste through certified channels.

- Supporting right-to-repair initiatives: Advocating for legislation that makes repairs more accessible.

The shift from a culture of disposable electronics to one that embraces longevity and resource efficiency requires a collective effort. It involves consumers making conscious purchasing decisions and actively participating in the circular economy. Public awareness campaigns, educational programs, and accessible recycling options are essential in fostering this change in behavior, thereby amplifying the effects of U.S. e-waste reduction initiatives.

Ultimately, the synergy between technological innovation, supportive policy, and responsible consumer actions forms the bedrock of a truly sustainable electronics ecosystem. Each component is interdependent, and strengthening one area inevitably bolsters the others, leading to greater overall progress in combating e-waste.

| Key Innovation | Impact on E-Waste |

|---|---|

| Advanced Materials Recovery | Extracts valuable materials from e-waste more efficiently, reducing landfill waste and reliance on virgin resources. |

| Modular Product Design | Extends device lifespan through repairability and upgradability, significantly delaying obsolescence and new purchases. |

| Combined Effect | Contributes to an estimated 20% annual reduction in U.S. e-waste through synergistic benefits. |

| Circular Economy Focus | Promotes resource longevity and regeneration, moving away from linear production models. |

Frequently asked questions about e-waste reduction

E-waste refers to discarded electronic devices. It’s a problem due to its rapid growth, containing toxic materials that harm the environment and human health, alongside valuable resources that are lost if not properly recycled. Effective management is crucial for sustainability.

Modular electronics are designed with easily replaceable components, allowing users to repair or upgrade parts instead of replacing the entire device. This significantly extends product lifespans, reducing the frequency of new purchases and thus decreasing e-waste generation.

Urban mining is the process of recovering valuable raw materials from discarded electronic products. It employs advanced techniques to extract metals like gold, silver, and rare earths from e-waste, reducing the need for traditional mining and its associated environmental impacts.

Yes, while currently concentrated in the U.S., the principles of advanced materials recovery and modular design are highly scalable. With international collaboration, investment in infrastructure, and supportive policies, these innovations can significantly contribute to global e-waste reduction efforts.

Consumers can contribute by choosing durable, repairable products, properly recycling old electronics through certified programs, and supporting brands committed to sustainable practices. Advocating for right-to-repair legislation also empowers consumers to extend device lifespans.

Conclusion

The emergence of two powerful U.S. sustainable tech innovations—advanced materials recovery and modular product design—marks a pivotal moment in the global fight against electronic waste. These advancements are collectively driving an estimated 20% annual reduction in e-waste, demonstrating that technological ingenuity can effectively address pressing environmental challenges. By transforming discarded electronics into valuable resources and extending the life of devices, these solutions are laying the groundwork for a truly circular economy. Their continued development, coupled with supportive policies and evolving consumer behavior, promises a future where technology is a force for environmental good, significantly mitigating the ecological footprint of our digital age.