Supply-chain disruptions weigh on manufacturing in the US

Supply-chain disruptions weigh on manufacturing in the US by increasing costs, delaying production timelines, and affecting overall productivity, necessitating technological adaptation and sustainable practices for effective mitigation.

Supply-chain disruptions weigh on manufacturing US, posing significant challenges that ripple across industries. Have you wondered how these setbacks affect production capabilities? Let’s delve into the specifics and explore the ramifications.

Understanding supply-chain disruptions

Understanding supply-chain disruptions is crucial in today’s manufacturing landscape. These disruptions can drastically alter production timelines and cost structures. They arise from various factors, including natural disasters, political instability, and global pandemics. Knowing the causes helps businesses prepare and adapt effectively.

Causes of Supply-Chain Disruptions

Several factors contribute to these interruptions. A few primary causes include:

- Natural disasters such as earthquakes or floods that damage transportation infrastructure.

- Political events that lead to trade embargoes and tariffs.

- Global health crises like pandemics that restrict movements and operations.

These disruptions create a ripple effect throughout industries, leading to shortages and delays. Understanding each cause can provide valuable insight into how to navigate challenges.

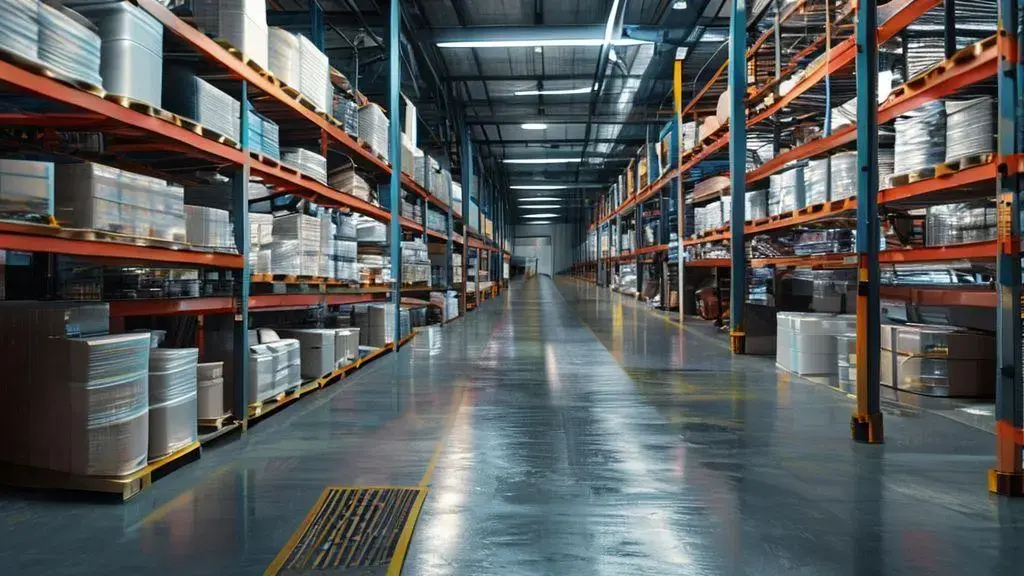

The Impact of Disruptions on Manufacturing

When supply chains are affected, manufacturers face significant challenges. Delayed shipments can halt production lines, leading to increased costs. Additionally, companies might struggle to meet customer demands, which can harm their reputation. Here are some effects manufacturers might experience:

- Increased operational costs due to expedited shipping.

- Decreased revenue from unmet orders.

- Loss of market share to competitors who adapt faster.

Overall, comprehending the impact of these disruptions is necessary for manufacturers to devise effective strategies.

Being aware of the common challenges can help companies implement stronger risk management techniques. Companies can explore alternatives such as diversifying suppliers and investing in technology to enhance their logistics. Ultimately, a proactive approach can decrease vulnerabilities and strengthen their strategies.

Impact on manufacturing productivity

The impact on manufacturing productivity due to supply-chain disruptions is significant. When disruptions occur, production schedules can be thrown off, leading to inefficiencies.

Effects of Disruptions

Manufacturers often experience a variety of negative effects when their supply chains are disrupted. Some common consequences include:

- Increased lead times for products.

- Higher costs associated with expedited shipping.

- Loss of staffing hours due to downtime.

- Decreased ability to meet customer demands.

These effects can result in lower overall output and profitability. As such, it is critical to comprehend how disruptions ripple through a manufacturing operation.

Adapting to Challenges

In response to these challenges, many manufacturers are adapting their strategies. Finding alternative suppliers can help ensure continuity. Additionally, embracing technology can streamline operations. For instance:

- Implementing supply chain management software can enhance visibility.

- Using data analytics allows for better decision-making.

- Automation can improve efficiency and reduce reliance on human labor.

By making these adjustments, manufacturers not only mitigate potential losses but may also uncover new opportunities for growth.

As companies face ongoing supply-chain challenges, maintaining flexibility and resilience becomes essential. Investing in strong relationships with suppliers and maintaining robust inventory levels can provide a buffer against unexpected disruptions. Additionally, focusing on workforce training ensures that employees are prepared for adapting to changes quickly.

Strategies to mitigate supply-chain issues

Implementing effective strategies to mitigate supply-chain issues is essential for manufacturers facing disruptions. These strategies not only enhance resilience but also improve overall efficiency.

Diversifying Suppliers

One of the key strategies is diversifying suppliers. Relying on a single supplier increases vulnerability to disruptions. By having multiple suppliers, businesses can reduce risks significantly. This approach involves:

- Identifying alternative suppliers in different regions.

- Building relationships with local vendors for quick access.

- Ensuring quality standards are consistent across suppliers.

Such diversification not only secures materials but also fosters healthy competition among suppliers, which may lower costs.

Adopting Technology Solutions

Leveraging technology can streamline operations and enhance communication. Implementing supply chain management (SCM) software can provide real-time data on inventory levels and shipments. Additionally:

- Data analytics can predict potential disruptions by monitoring trends.

- Cloud-based solutions allow for better collaboration with partners.

- Automation in warehousing can speed up processes.

These technological adaptations create a more agile supply chain, ready to respond to changes swiftly.

A proactive approach is vital. Building a responsive supply chain requires fostering strong relationships with partners. Regularly communicating and collaborating with suppliers keeps everyone informed about potential risks. Another essential aspect is investing in employee training, ensuring that staff are prepared to adapt to new processes and tools.

The future of manufacturing and supply chains

The future of manufacturing and supply chains is being reshaped by technology and global trends. As businesses adapt to changing conditions, several key factors will play a role in this evolution.

Technological Advancements

Technology is one of the main driving forces behind changes in manufacturing. Automation and robotics are streamlining production processes. Companies are also adopting artificial intelligence to enhance decision-making. Important technologies include:

- Advanced robotics for precision and efficiency.

- Internet of Things (IoT) devices for real-time tracking.

- Data analytics for predicting trends and managing risks.

These advancements allow manufacturers to operate more efficiently and respond quickly to supplier disruptions.

Shift Towards Sustainability

Sustainability is becoming a top priority in the manufacturing sector. Companies are recognizing the need to minimize their environmental impact. This shift involves using eco-friendly materials and reducing waste. Some important aspects include:

- Investing in renewable energy sources.

- Implementing closed-loop systems to recycle materials.

- Adopting sustainable production practices.

Such measures not only benefit the environment but also appeal to environmentally conscious consumers.

Collaboration is vital for the future of supply chains. Companies are increasingly working together to enhance resilience. By sharing information and resources, they can better navigate challenges. Additionally, embracing a flexible supply chain model will help companies adjust to market demands more effectively.

As industries evolve, the integration of technology and sustainable practices will pave the way for a more efficient manufacturing landscape. Companies that invest in innovation and sustainability are likely to stay ahead in an increasingly competitive global market.

FAQ – Frequently Asked Questions about the Future of Manufacturing and Supply Chains

How will technology affect the future of manufacturing?

Technology, such as automation and AI, will enhance efficiency and decision-making in manufacturing processes.

What role does sustainability play in modern manufacturing?

Sustainability is crucial as it reduces environmental impact and meets the demands of eco-conscious consumers.

Why is collaboration important in supply chains?

Collaboration helps businesses share resources and information, which enhances their ability to cope with challenges.

How can companies adapt to new market demands?

Companies can remain agile by diversifying suppliers and investing in technology to improve flexibility.