Advanced Material Science: 5 Composites Revolutionizing US Infrastructure by 2026

Advanced material science is ushering in a new era for U.S. infrastructure. By 2026, five innovative composite materials will revolutionize construction, enhancing durability, reducing maintenance, and boosting efficiency across critical projects.

The landscape of American infrastructure is on the cusp of a profound transformation, driven by breakthroughs in advanced material science. By 2026, the integration of five groundbreaking composite materials is set to fundamentally reshape how the U.S. approaches its critical infrastructure projects, promising unprecedented durability, efficiency, and sustainability.

The urgent need for infrastructure innovation in the U.S.

The United States faces a significant challenge with its aging infrastructure. Roads, bridges, pipelines, and public buildings nationwide are in dire need of repair, replacement, or modernization. Traditional construction materials, while historically reliable, often fall short when confronted with contemporary demands for extended lifespan, reduced maintenance, and environmental resilience. This pressing need has fueled an intensive search for innovative solutions, propelling advanced material science to the forefront of infrastructure development.

For decades, concrete and steel have been the bedrock of construction. However, their inherent limitations, such as susceptibility to corrosion, fatigue, and heavy weight, contribute to escalating maintenance costs and shorter service lives. The environmental impact of producing these materials also presents a growing concern. As a result, engineers and scientists are increasingly turning to composite materials, which offer superior performance characteristics tailored to the specific demands of modern infrastructure projects. These new materials are not just incremental improvements; they represent a paradigm shift in how we conceive, build, and maintain our vital public assets.

Addressing the challenges of traditional materials

- Corrosion Resistance: Unlike steel, many advanced composites are inherently resistant to rust and chemical degradation, drastically extending the lifespan of structures in harsh environments.

- Lightweight Strength: Composites often possess a higher strength-to-weight ratio than traditional materials, reducing dead loads, easing transportation, and simplifying installation processes.

- Durability and Longevity: Designed to withstand extreme weather, seismic activity, and heavy usage, these materials promise a significantly longer service life, minimizing the frequency and cost of repairs.

- Reduced Maintenance: The enhanced resilience of composites translates directly into lower long-term maintenance requirements, freeing up resources for new projects and critical upgrades.

The drive for innovation is not merely about replacing old with new, but about strategically investing in materials that offer a superior return on investment over the entire lifecycle of an infrastructure project. The economic and societal benefits of such an approach are immense, ranging from safer public spaces to more efficient transportation networks. This proactive embrace of advanced material science is critical for building a resilient and sustainable future for U.S. infrastructure.

Fiber-reinforced polymer (FRP) composites: a new structural backbone

Fiber-reinforced polymer (FRP) composites are already gaining traction, but their applications are set to expand dramatically by 2026, establishing them as a new structural backbone for U.S. infrastructure. These materials combine high-strength fibers, such as carbon, glass, or aramid, with a polymer matrix, resulting in a lightweight yet incredibly strong and corrosion-resistant material. Their versatility makes them ideal for a wide range of structural applications, from reinforcing concrete to constructing entire bridge decks.

One of the most compelling advantages of FRPs is their immunity to rust. This characteristic is particularly vital for coastal infrastructure, bridges exposed to de-icing salts, and underground piping systems where corrosion is a perpetual and costly problem. By eliminating the need for corrosion protection, FRPs simplify construction, reduce long-term maintenance, and extend the service life of critical assets. Their high strength-to-weight ratio also means lighter components, which can be prefabricated off-site and rapidly installed, significantly cutting down construction time and disruption.

Applications revolutionizing construction

- Bridge Decks and Girders: FRPs are being used for entire bridge decks, offering lighter structures that are easier to transport and install, and are impervious to the elements.

- Rebar and Tendons: Replacing traditional steel rebar with FRP alternatives in concrete structures eliminates corrosion concerns, particularly in marine environments or structures exposed to aggressive chemicals.

- Structural Strengthening: FRP laminates and wraps are applied to existing concrete and steel structures to enhance their load-bearing capacity and seismic resilience without adding significant weight.

- Pipelines and Storage Tanks: Their chemical resistance makes FRPs ideal for water, wastewater, and chemical storage applications, ensuring long-term integrity and preventing leaks.

The adoption of FRP composites is not just about material substitution; it represents an opportunity to design and build infrastructure that is fundamentally more durable and sustainable. As manufacturing processes become more efficient and costs continue to decrease, FRPs are poised to become a standard material in the U.S. infrastructure toolkit, ensuring a more resilient and future-proof built environment. The shift towards these advanced materials marks a significant step forward in addressing the nation’s infrastructure challenges effectively.

Self-healing concrete: the future of durable roadways

Imagine concrete that can repair its own cracks, extending the life of roadways and structures without human intervention. This seemingly futuristic concept is rapidly becoming a reality with the advent of self-healing concrete, a material set to redefine durability in U.S. infrastructure by 2026. This innovative composite incorporates various mechanisms, such as encapsulated healing agents or bacteria, that activate upon crack formation, autonomously sealing damage and preventing further deterioration.

The primary benefit of self-healing concrete is its ability to significantly reduce maintenance costs and prolong the service life of concrete infrastructure. Cracks, often caused by thermal expansion, heavy loads, or freeze-thaw cycles, are a major pathway for water and corrosive agents to penetrate, leading to accelerated degradation. By automatically sealing these cracks, self-healing concrete mitigates these issues, ensuring the structural integrity of roads, bridges, and buildings for decades longer than conventional concrete.

Mechanisms for autonomous repair

- Bacterial Healing: Spores of bacteria are embedded within the concrete. When cracks appear and water infiltrates, the bacteria activate, producing calcium carbonate which fills and seals the cracks.

- Encapsulated Polymers: Microcapsules containing healing agents, like polymers or epoxies, are dispersed throughout the concrete. When a crack forms, the capsules rupture, releasing the agent to fill and bond the crack surfaces.

- Vascular Networks: Inspired by biological systems, some designs incorporate hollow tubes or networks within the concrete that release healing agents when damaged, similar to how blood vessels clot.

Beyond cost savings, self-healing concrete also enhances the sustainability of infrastructure. By extending the lifespan of structures, it reduces the demand for new materials and the energy associated with their production and transportation. It also minimizes the waste generated from demolition and reconstruction. As research progresses and these technologies become more scalable and cost-effective, self-healing concrete is poised to become a standard component in the construction of resilient and long-lasting U.S. infrastructure, ensuring a more robust and sustainable built environment for future generations.

High-performance geopolymers: sustainable and robust alternatives

High-performance geopolymers represent a significant leap forward in sustainable construction, offering robust alternatives to traditional Portland cement. These inorganic polymer composites are formed from aluminosilicate materials, often industrial by-products like fly ash or slag, activated by an alkaline solution. By 2026, geopolymers are expected to play a crucial role in U.S. infrastructure projects, particularly where environmental impact and superior performance are paramount.

The main advantage of geopolymers lies in their significantly lower carbon footprint compared to conventional cement. Portland cement production is a major contributor to global CO2 emissions, whereas geopolymers can reduce these emissions by up to 80% by utilizing waste materials and requiring less energy-intensive manufacturing processes. Beyond their environmental benefits, geopolymers also boast exceptional mechanical properties, including high compressive strength, excellent fire resistance, and superior durability against chemical attack and abrasion.

Key benefits for infrastructure development

- Reduced Carbon Emissions: Utilizing industrial waste products as precursors significantly lowers the embodied carbon of construction materials, aligning with green building initiatives.

- Enhanced Durability: Geopolymers exhibit superior resistance to sulfates, acids, and chlorides, making them ideal for aggressive environments such such as wastewater treatment plants or coastal structures.

- Fire Resistance: Their inorganic nature provides inherent fire resistance, far surpassing that of ordinary concrete, offering enhanced safety in tunnels and high-rise buildings.

- Rapid Strength Gain: Many geopolymer formulations can achieve high strength much faster than Portland cement, accelerating construction schedules and reducing project timelines.

The adoption of high-performance geopolymers is not without its challenges, primarily related to standardization, perception, and initial cost. However, as the construction industry increasingly prioritizes sustainable practices and long-term performance, the unique combination of environmental benefits and superior material properties offered by geopolymers makes them an indispensable component of future U.S. infrastructure. Their continued integration will pave the way for greener, more resilient, and ultimately more cost-effective construction solutions across the nation.

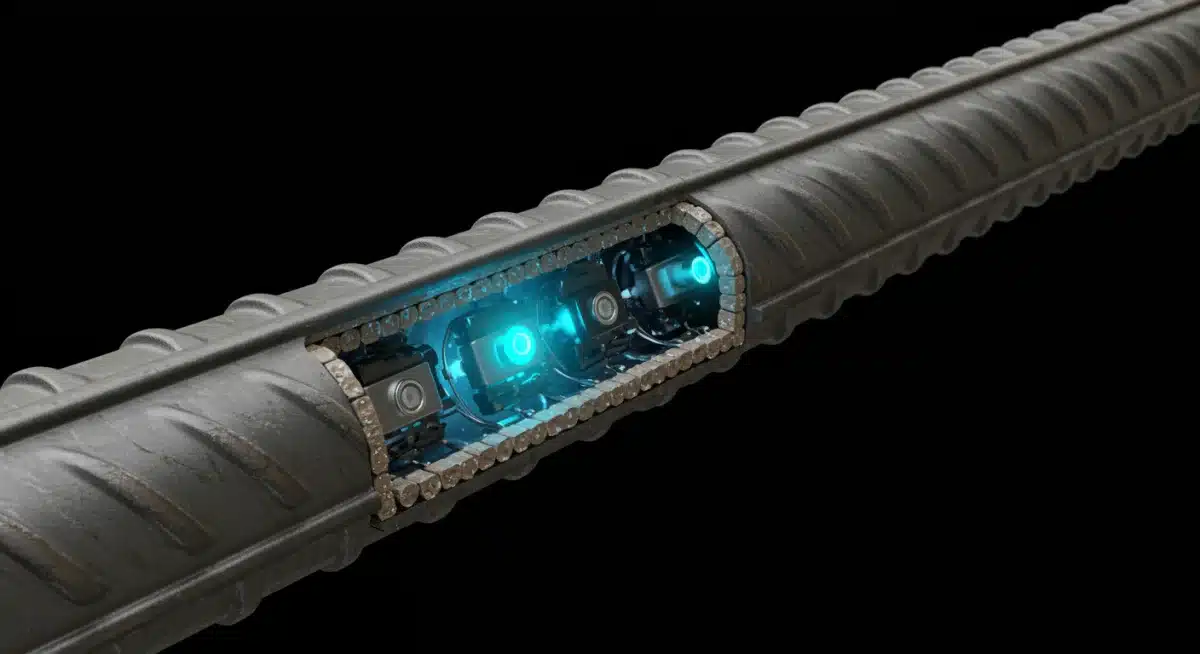

Smart composites with embedded sensors: intelligent infrastructure

The next frontier in advanced material science for infrastructure is the integration of smart composites with embedded sensors. By 2026, these intelligent materials will transform passive structures into active, self-monitoring systems, providing real-time data on their structural health and performance. This innovation promises to revolutionize maintenance strategies, enabling predictive rather than reactive interventions and significantly enhancing the safety and longevity of U.S. infrastructure.

These smart composites, often fiber-reinforced polymers or advanced concrete formulations, incorporate various types of sensors: fiber optics for strain and temperature monitoring, piezoelectric sensors for vibration and impact detection, and even humidity sensors to detect moisture ingress. This embedded intelligence allows for continuous, non-destructive evaluation of a structure’s condition, identifying potential issues long before they become critical. Imagine a bridge that can autonomously report a developing crack or a pipeline that alerts operators to a weak point before a leak occurs.

Transforming maintenance and safety protocols

- Real-time Structural Health Monitoring: Continuous data acquisition allows engineers to assess structural integrity, detect anomalies, and predict potential failures, moving away from scheduled, often inefficient, manual inspections.

- Optimized Maintenance Schedules: By understanding the actual condition of infrastructure, maintenance can be performed precisely when and where it is needed, reducing unnecessary repairs and extending asset life.

- Enhanced Safety: Early detection of structural degradation or damage significantly reduces the risk of catastrophic failures, protecting public safety and minimizing economic disruption.

- Data-driven Decisions: The wealth of data collected from embedded sensors provides invaluable insights for future design improvements and material selection, fostering a cycle of continuous innovation.

The development and widespread adoption of smart composites with embedded sensors represent a monumental shift towards truly intelligent infrastructure. This technology not only promises to make U.S. infrastructure safer and more durable but also more efficient and cost-effective to manage over its entire lifecycle. As these systems become more sophisticated and integrated, they will lay the groundwork for a seamlessly monitored and responsive built environment, ushering in an era of unprecedented reliability and performance.

Bio-inspired and nature-based composites: sustainable and resilient solutions

Drawing inspiration from the unparalleled efficiency and resilience found in natural systems, bio-inspired and nature-based composites are emerging as a powerful force in advanced material science. By 2026, these innovative materials will offer sustainable and inherently resilient solutions for U.S. infrastructure, mimicking biological structures to achieve superior performance with minimal environmental impact. This approach represents a paradigm shift from traditional engineering, embracing nature’s wisdom for robust and eco-friendly construction.

These composites often incorporate natural fibers (like basalt, hemp, or flax) with bio-derived resins or utilize hierarchical structures found in bone or nacre. The goal is to create materials that are not only strong and durable but also lightweight, self-healing, and environmentally benign. For instance, some materials are designed to absorb impact energy like a seashell or to self-regulate temperature like a plant leaf. This biomimicry leads to materials with extraordinary properties that are difficult to achieve through conventional synthetic means.

Embracing nature’s engineering principles

- Self-Healing Properties: Similar to how biological tissues repair themselves, some bio-inspired composites are being developed with intrinsic self-healing capabilities, extending their lifespan.

- Lightweight and High Strength: Emulating cellular structures or fiber arrangements found in nature can yield materials with exceptional strength-to-weight ratios, reducing material usage and transportation costs.

- Sustainable Sourcing: Utilizing abundant natural fibers and bio-derived resins reduces reliance on fossil fuels and lowers the carbon footprint of construction materials.

- Adaptability and Resilience: Designing materials that can adapt to environmental changes or dissipate energy effectively, much like biological systems, enhances the overall resilience of infrastructure against extreme events.

The integration of bio-inspired and nature-based composites into U.S. infrastructure projects is a testament to the growing commitment to sustainability and long-term resilience. These materials not only offer a path to greener construction but also promise structures that are inherently more robust and capable of enduring the challenges of a changing climate. As research in biomimicry advances, these innovative composites will increasingly provide elegant and effective solutions for building the next generation of American infrastructure, blending cutting-edge science with ecological wisdom.

Economic and environmental impacts of composite adoption

The widespread adoption of advanced composites in U.S. infrastructure projects by 2026 is poised to deliver significant economic and environmental benefits. Beyond the immediate advantages of improved structural performance, these materials offer a compelling case for long-term savings, reduced ecological footprint, and enhanced societal well-being. The initial investment in these cutting-edge materials is often offset by substantial lifecycle cost reductions.

Economically, the primary impact stems from reduced maintenance and extended service life. Infrastructure assets built with composites require less frequent repairs and replacements, translating into lower operational expenses for state and federal agencies. Furthermore, faster construction times, due to prefabrication and lighter components, can minimize labor costs and reduce economic disruptions caused by prolonged construction. The creation of new industries and jobs associated with the manufacturing and installation of these specialized materials also provides a substantial economic boost.

Driving sustainability and resilience

- Lower Lifecycle Costs: Reduced maintenance, longer lifespan, and faster construction lead to significant cost savings over the entire operational period of infrastructure assets.

- Reduced Carbon Footprint: Many composites, especially geopolymers and bio-inspired materials, utilize recycled content or have lower energy requirements for production, contributing to reduced greenhouse gas emissions.

- Waste Reduction: More durable structures generate less demolition waste, and the use of industrial by-products in geopolymers diverts waste from landfills.

- Job Creation: The burgeoning advanced materials sector creates new opportunities in research, manufacturing, engineering, and construction, fostering innovation and economic growth.

Environmentally, the shift towards composites aligns perfectly with national sustainability goals. By reducing the demand for raw materials, lessening energy consumption in production, and extending the life of structures, these materials contribute to a more circular economy. The enhanced resilience of composite structures against extreme weather events also minimizes the need for rebuilding after disasters, further reducing environmental impact. Ultimately, the integration of advanced composites is not just an engineering choice but a strategic investment in a more sustainable, resilient, and economically vibrant future for U.S. infrastructure.

| Composite Material | Key Benefit for Infrastructure |

|---|---|

| Fiber-Reinforced Polymers (FRP) | Corrosion resistance, high strength-to-weight ratio, rapid installation. |

| Self-Healing Concrete | Autonomous crack repair, extended service life, reduced maintenance. |

| High-Performance Geopolymers | Lower carbon footprint, superior durability against chemicals/fire. |

| Smart Composites with Sensors | Real-time structural health monitoring, predictive maintenance, enhanced safety. |

Frequently asked questions about advanced composites in infrastructure

Advanced composites offer superior properties like corrosion resistance, higher strength-to-weight ratios, and enhanced durability. This leads to longer service lives, reduced maintenance costs, and improved resilience against environmental factors compared to conventional steel and concrete.

Self-healing concrete contains embedded agents, such as bacteria or microcapsules with polymers. When cracks form, these agents are released or activated, initiating a chemical reaction that fills and seals the cracks autonomously, preventing further damage and water ingress.

Yes, geopolymers are significantly more sustainable. They typically utilize industrial waste products like fly ash, reducing landfill burden, and their production process generates up to 80% less carbon dioxide compared to the manufacturing of Portland cement, making them eco-friendly.

Embedded sensors transform composites into intelligent materials capable of real-time structural health monitoring. They detect strain, temperature, and damage, providing continuous data that enables predictive maintenance, enhances safety, and extends the operational life of infrastructure assets.

Bio-inspired composites leverage natural designs for enhanced properties like self-healing, lightweight strength, and adaptability. They offer sustainable sourcing, reduce environmental impact, and create structures with superior resilience, drawing lessons from nature’s efficient engineering to build more robust infrastructure.

Conclusion

The integration of advanced material science, particularly the five composite innovations discussed, is not merely an incremental upgrade for U.S. infrastructure but a fundamental redefinition of its future. By 2026, fiber-reinforced polymers, self-healing concrete, high-performance geopolymers, smart composites with embedded sensors, and bio-inspired materials will collectively usher in an era of unprecedented durability, sustainability, and intelligent management. These materials promise to deliver infrastructure that is not only robust and long-lasting but also environmentally responsible and economically efficient, safeguarding public safety and supporting national growth for generations to come. The proactive adoption of these composites is crucial for building a resilient, modern America.