Digital Twins: How Companies Optimize with Virtual Replicas & Save Costs

Digital twins are revolutionizing industries by providing virtual replicas of physical assets, enabling companies to optimize operations, predict failures, and achieve significant cost savings, often around 15%.

Discover how digital twins are transforming industries by offering virtual replicas of physical assets, leading to optimized operations and considerable cost savings.

Understanding Digital Twins: A Comprehensive Overview

Digital twins are more than just 3D models; they are dynamic virtual representations of physical assets, processes, or systems. They bridge the gap between the physical and digital worlds, enabling real-time monitoring, simulation, and optimization.

What Exactly is a Digital Twin?

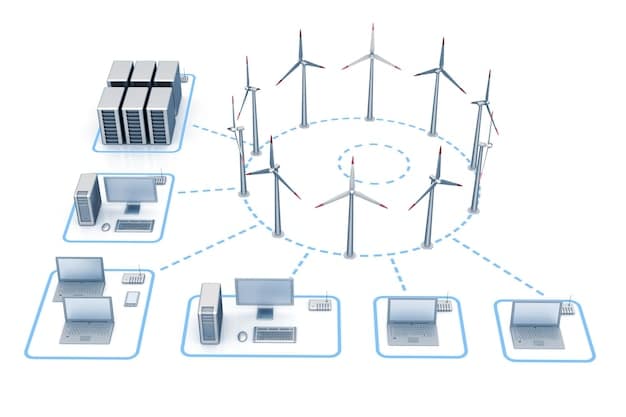

At its core, a digital twin is a virtual copy of a physical entity. This could be anything from a single machine to an entire factory, a power grid, or even a city. The key is that the digital twin is connected to its physical counterpart through sensors and data streams.

These data streams provide real-time information about the physical asset’s performance, condition, and environment. This data is then used to update the digital twin, ensuring that it accurately reflects the state of the physical asset.

The Key Components of a Digital Twin

A robust digital twin consists of several essential components that work together to provide a comprehensive virtual representation of a physical asset or system.

- Physical Asset: The real-world object or system being replicated. This could be anything from a single machine to an entire factory or even a city.

- Sensors and Data Streams: Devices that gather real-time data from the physical asset, such as temperature, pressure, vibration, and location. This data is fed into the digital twin to keep it updated.

- Digital Model: A virtual representation of the physical asset, built using CAD, simulation software, and other tools. This model is constantly updated with data from the sensors.

- Analytics and Algorithms: Software that processes the data from the sensors and the digital model to identify patterns, predict failures, and optimize performance.

In essence, a digital twin is a living model that evolves as its physical counterpart changes. This dynamic representation allows organizations to gain valuable insights, make informed decisions, and optimize their operations in ways that were previously impossible.

In conclusion, understanding the foundational elements of digital twins—the blend of physical data and virtual modeling—is critical to realizing their potential for cost savings and innovation.

Cost Savings: How Digital Twins Drive Efficiency

One of the most compelling benefits of digital twins is their ability to generate significant cost savings. By providing insights into asset performance and enabling proactive maintenance, digital twins help companies optimize their operations and reduce expenses.

Predictive Maintenance and Reduced Downtime

Traditional maintenance strategies often involve scheduled maintenance, which can be inefficient and costly. Digital twins enable predictive maintenance by analyzing real-time data to identify potential failures before they occur.

This allows companies to perform maintenance only when it is needed, reducing downtime and extending the lifespan of their assets. For example, a digital twin of a jet engine can analyze vibration data to predict when a component is likely to fail, allowing the airline to schedule maintenance before a costly in-flight failure occurs.

Optimized Operations and Resource Management

Digital twins also help companies optimize their operations by simulating different scenarios and identifying the most efficient ways to use their resources. Consider the following points:

- Energy Consumption: Digital twins can monitor energy consumption and identify areas where energy is being wasted.

- Supply Chain Optimization: Digital twins can simulate different supply chain scenarios to identify bottlenecks and optimize logistics.

- Manufacturing Processes: Digital twins can simulate manufacturing processes to identify areas where production can be improved.

Case Studies: Real-World Examples of Cost Savings

Several companies have already realized significant cost savings by implementing digital twins. Here are a few examples:

GE used digital twins to improve the efficiency of its power plants, resulting in millions of dollars in savings. Siemens used digital twins to optimize the design of its trains, reducing development time and costs. Boeing used digital twins to improve the efficiency of its aircraft manufacturing processes, reducing waste and improving quality.

In short, digital twins are proving to be valuable tools for slashing operational costs and boosting efficiency through predictive maintenance and optimizing resource allocation.

Real-World Applications of Digital Twins Across Industries

The applications of digital twins span across various industries, each leveraging the technology to improve efficiency, reduce costs, and enhance decision-making. From manufacturing to healthcare, digital twins are reshaping how businesses operate.

Manufacturing: Optimizing Production Lines

In manufacturing, digital twins are used to create virtual replicas of production lines, allowing companies to simulate and optimize their processes before implementing changes in the physical world.

This can lead to significant improvements in efficiency, reduced waste, and faster time-to-market. For instance, a digital twin can be used to optimize the layout of a factory floor, identify bottlenecks in the production process, and test different scenarios to improve throughput.

Healthcare: Personalized Treatment and Device Development

Digital twins are also making inroads into the healthcare industry, where they are being used to create virtual replicas of patients and medical devices. This allows doctors to personalize treatment plans and medical device manufacturers to test and optimize their products.

Aerospace: Enhancing Aircraft Design and Maintenance

The aerospace industry has been an early adopter of digital twin technology. Digital twins of aircraft engines and airframes allow engineers to monitor performance, predict maintenance needs, and optimize designs for fuel efficiency and safety.

Implementing Digital Twins: Key Considerations

Implementing a digital twin strategy requires careful planning and consideration of several key factors, including data management, technology infrastructure, and organizational culture. A well-executed implementation can lead to significant benefits, while a poorly planned one can result in wasted resources and missed opportunities.

Defining Objectives and Scope

Before embarking on a digital twin project, it is essential to define clear objectives and scope. What problems are you trying to solve? What assets or processes will be included in the digital twin? What data will be collected and analyzed?.

Choosing the Right Technology Platform

Selecting the right technology platform is crucial for the success of a digital twin project. There are several platforms available, each with its own strengths and weaknesses. Consider factors such as scalability, interoperability, and ease of use.

- Cloud Platforms: Platforms like AWS, Azure, and Google Cloud offer robust digital twin capabilities.

- Specialized Software: Software like Siemens MindSphere, GE Predix, and Dassault Systèmes 3DExperience platform provide specialized tools.

- Open Source: Open-source platforms such as Eclipse Ditto offer flexibility and customization.

Data Integration and Management

A digital twin is only as good as the data that feeds it. It is essential to have a robust data integration and management strategy in place to ensure that data is accurate, timely, and relevant. This includes defining data sources, establishing data quality standards, and implementing data governance policies.

In summary, carefully defining objectives, choosing the right technological tools, and managing data effectively are crucial for successfully employing digital twins and accruing their advantages.

The Future of Digital Twins: Trends and Predictions

The field of digital twins is rapidly evolving, with new technologies and applications emerging all the time. Several trends are shaping the future of digital twins, including advancements in artificial intelligence, the Internet of Things (IoT), and augmented reality (AR).

Integration with Artificial Intelligence (AI)

AI is playing an increasingly important role in digital twins, enabling them to perform more advanced analytics and make more intelligent decisions. AI algorithms can be used to analyze data from digital twins to identify patterns, predict failures, and optimize operations.

The Role of the Internet of Things (IoT)

The IoT is providing the data that fuels digital twins. As more and more devices become connected, the amount of data available for digital twins is growing exponentially. This data can be used to create more accurate and detailed virtual representations of physical assets.

Augmented Reality (AR) and Digital Twins

AR is also being integrated with digital twins, allowing users to visualize and interact with digital twins in the real world. This can be used for training, maintenance, and remote collaboration. For example, a technician can use an AR headset to overlay a digital twin of a machine onto the physical machine, providing real-time information and guidance.

Overcoming Challenges and Maximizing ROI

While digital twins offer numerous benefits, implementing them successfully can be challenging. Organizations often face obstacles related to data integration, technology infrastructure, and organizational culture. Overcoming these challenges is crucial for maximizing the return on investment (ROI) from digital twin initiatives.

Addressing Data Integration Challenges

One of the biggest challenges in implementing digital twins is integrating data from multiple sources. This data may be stored in different formats, located in different systems, and owned by different departments. Addressing these challenges requires a comprehensive data integration strategy, including data standardization, data governance, and data integration tools.

Building a Robust Technology Infrastructure

Digital twins require a robust technology infrastructure, including sensors, data storage, computing power, and software. Organizations need to invest in the right technology and ensure that it is scalable, reliable, and secure. This may involve upgrading existing systems, deploying new infrastructure, or using cloud-based services.

Fostering a Data-Driven Culture

To fully realize the benefits of digital twins, organizations need to foster a data-driven culture. This means encouraging employees to use data to make decisions, providing training on data analysis tools, and creating incentives for data sharing and collaboration. It also involves breaking down silos between departments and promoting a holistic view of data.

| Key Point | Brief Description |

|---|---|

| 💡 Cost Savings | Optimize operations and reduce expenses by predicting failures and proactively maintaining assets. |

| ⚙️ Predictive Maintenance | Analyze real-time data to identify potential issues before they cause downtime, saving time and money. |

| 📊 Data Integration | A robust strategy to ensure accurate, timely, and relevant data for digital twin functionality. |

| 🤖 AI Integration | AI algorithms analyze data to predict failures and optimize operations intelligently. |

FAQ

▼

The primary benefit is significant cost savings through optimized operations, predictive maintenance, and efficient resource management, typically around 15%.

▼

Digital twins are widely used in manufacturing, healthcare, aerospace, and smart cities to enhance efficiency and decision-making processes.

▼

Real-time data from sensors, historical data, and simulation models are used to create and maintain an accurate digital twin representation.

▼

Digital twins analyze real-time data to predict potential failures, allowing for proactive maintenance that reduces downtime and extends asset lifespan.

▼

AI algorithms enhance digital twins by analyzing data, identifying patterns, and optimizing operations, leading to more intelligent and efficient decision-making.

Conclusion

In conclusion, the rise of digital twins signifies a paradigm shift in how businesses optimize operations and achieve cost savings. By embracing this technology, companies can unlock new levels of efficiency, reduce downtime, and make more informed decisions, ultimately driving greater success in an increasingly competitive landscape.